Accessibility is no longer an optional feature in passenger elevator design—it is a basic requirement for modern buildings. With increasing urban density and aging populations, elevators must safely and comfortably serve wheelchair users, elderly passengers, and people with limited mobility across residential, commercial, and public spaces.

Accessible elevator design goes beyond compliance. It involves thoughtful integration of cabin layout, door systems, control interfaces, ride accuracy, and safety functions to reduce physical barriers and improve usability. For developers and building owners, well-designed accessible elevators also help meet international standards, enhance building value, and avoid costly future modifications.

Delfar incorporates accessibility requirements into the early stages of passenger elevator design, delivering practical and compliant solutions suited for global projects.

In passenger elevator engineering, accessibility refers to designing systems that can be used safely, comfortably, and independently by people with different physical abilities. This includes not only wheelchair users, but also elderly passengers, people with visual or hearing impairments, and users with temporary mobility limitations. Accessibility-focused design requires a systematic approach that combines international standards, ergonomic principles, and real-world usage scenarios. Rather than adding features later, accessibility should be integrated into the elevator’s core design to ensure consistency, safety, and long-term reliability.

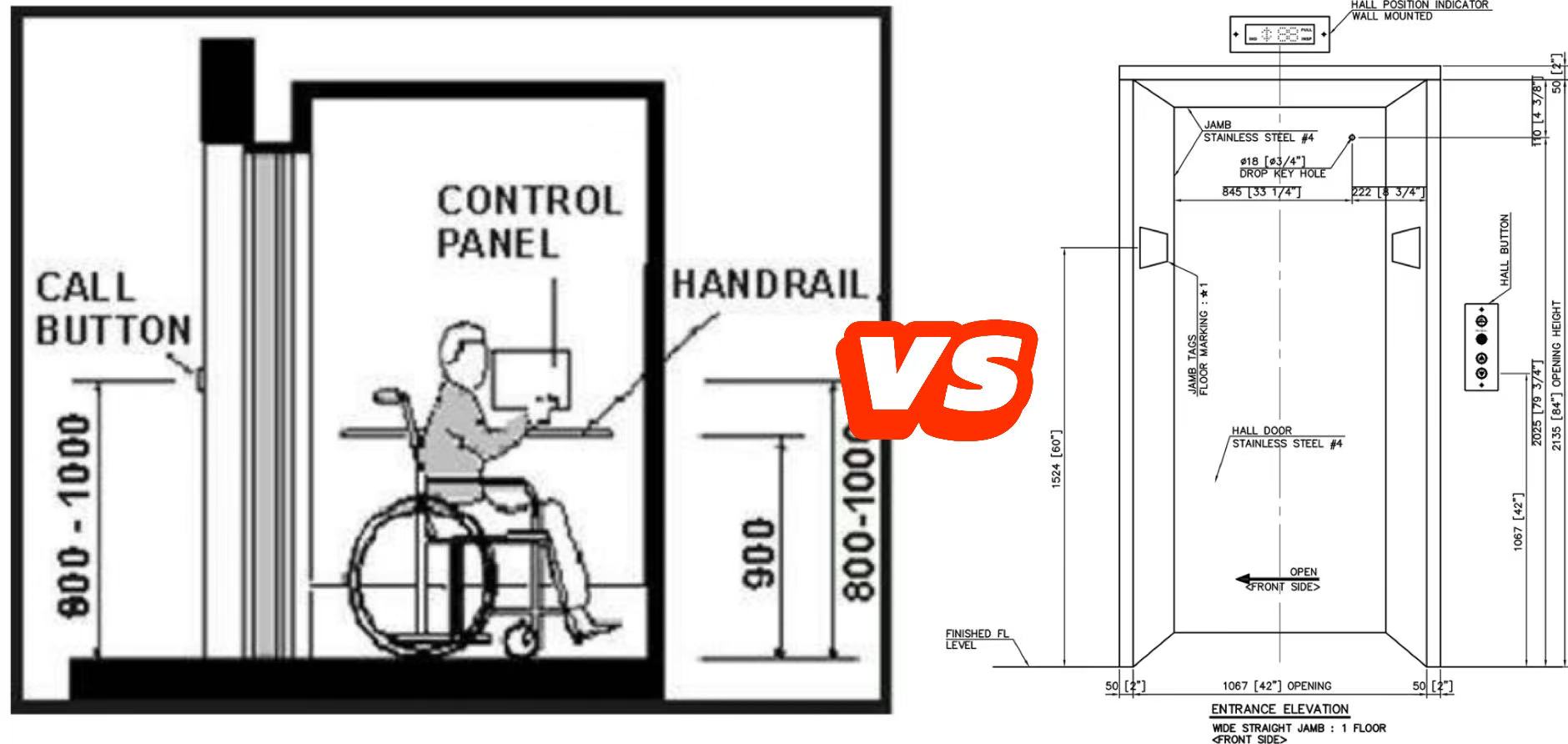

Compared with standard passenger elevators, accessible elevators place greater emphasis on space, interface usability, and operational precision. Cabin dimensions must allow sufficient turning radius for wheelchairs, while door opening widths and timing must accommodate slower entry and exit. Control panels are positioned at reachable heights and often include tactile markings or Braille. In addition, higher requirements are placed on leveling accuracy to prevent trip hazards. These differences ensure that all passengers can use the elevator independently, without assistance or risk.

Accessible passenger elevators are commonly required in a wide range of building types. Residential buildings must support long-term daily use by aging occupants, while hospitals and healthcare facilities demand smooth operation and precise leveling for beds and wheelchairs. Commercial buildings, hotels, and shopping centers rely on accessible elevators to serve high passenger volumes and comply with public access regulations. In many countries, public infrastructure and government-funded projects mandate accessibility as a baseline requirement rather than an optional upgrade.

Accessible passenger elevator design is strongly influenced by international standards and regional building codes. These regulations define minimum technical requirements to ensure elevators can be safely and independently used by passengers with reduced mobility. For manufacturers, contractors, and developers, understanding these standards at the design stage is essential to avoid compliance risks, project delays, or costly redesigns. From cabin dimensions to control interfaces and safety functions, accessibility standards provide a clear engineering framework that aligns safety, usability, and legal responsibility across global markets.

Among the most widely referenced standards, EN 81-20 establishes comprehensive safety requirements for passenger elevators, while EN 81-70 specifically focuses on accessibility, including cabin size, door width, control panel layout, and user information systems. These standards are commonly adopted or referenced beyond Europe, influencing specifications in the Middle East, Asia, and other international markets. In addition, ISO-related ergonomic principles support human-centered design, ensuring elevator systems accommodate diverse physical capabilities without compromising safety or performance.

In practical project tenders, accessibility requirements are often clearly defined and non-negotiable. Common specifications include minimum cabin dimensions suitable for wheelchairs, clear door opening widths, and accessible COP and LOP heights. Audible floor announcements and visual indicators are frequently required for users with visual or hearing impairments. Precise leveling accuracy is also emphasized to reduce trip risks. For suppliers, meeting these tender requirements demonstrates technical competence and significantly improves competitiveness in public and international projects.

Effective accessibility design in passenger elevators is achieved through a combination of spatial planning, mechanical precision, and user-oriented interfaces. These elements must work together to eliminate physical barriers while maintaining safe and efficient operation. From the size of the cabin to the responsiveness of the control system, each design decision directly affects how easily different users can enter, operate, and exit the elevator. A well-designed accessible elevator improves passenger confidence and reduces the need for assistance in daily use.

Cabin dimensions are a critical factor in accessibility. Adequate internal space allows wheelchair users to enter, turn, and exit safely without obstruction. Layout design often includes strategically positioned handrails to provide stability for standing passengers while avoiding interference with wheelchair movement. Mirrors or reflective panels are commonly installed to improve spatial awareness and assist wheelchair users when reversing out of the cabin. All interior elements must be securely mounted and aligned to ensure safety during operation.

Door systems play a decisive role in passenger accessibility. Sufficient clear opening width is essential for wheelchairs, medical equipment, and mobility aids. Door opening and closing speeds must be carefully controlled to allow safe entry and exit, especially for elderly users. Infrared light curtain protection systems are widely adopted to prevent doors from closing when passengers are detected in the doorway. These features collectively reduce accident risk and improve overall usability.

Accessible control panel design focuses on reachability, clarity, and intuitive operation. Car Operating Panels and Landing Operating Panels are installed at heights that can be easily reached from a seated position. Buttons often feature tactile symbols or Braille markings to support visually impaired users. Clear visual indicators and optional voice announcements provide real-time feedback on elevator status, improving user confidence and minimizing operational errors.

Ride comfort and leveling precision are essential for accessible elevator use. Accurate leveling ensures that the cabin floor aligns closely with the landing floor, reducing trip hazards and facilitating smooth wheelchair movement. Advanced VVVF control and permanent magnet synchronous drive systems contribute to smooth acceleration, deceleration, and minimal vibration. Stable ride quality is particularly important in hospitals and residential buildings, where passengers may be more sensitive to sudden movements.

Safety systems are a fundamental part of accessible passenger elevator design, as vulnerable users often rely on predictable and secure operation. For elderly passengers, wheelchair users, and people with limited mobility, safety features are not only protective measures but also essential for independent use. Modern passenger elevators integrate multiple layers of mechanical and electronic protection to minimize risk during normal operation and emergency situations.

Advanced braking systems are critical to ensuring safe and stable elevator operation. Dual circuit braking systems provide redundancy, ensuring that braking performance is maintained even if one circuit fails. Upward and downward overspeed protection systems continuously monitor elevator speed and trigger safety mechanisms if abnormal conditions are detected. These features are particularly important for accessible elevators, as sudden stops or uncontrolled movement can pose higher risks to passengers with reduced balance or mobility.

Emergency systems must be designed with accessibility in mind. Emergency lighting ensures visibility inside the cabin during power failures, helping passengers remain calm and oriented. Two-way intercom systems allow passengers to communicate with rescue personnel without needing physical strength or complex操作. Firefighter operation functions enable controlled elevator use during emergencies, while clear visual and audible signals help users understand the elevator’s status and instructions, reducing panic and confusion.

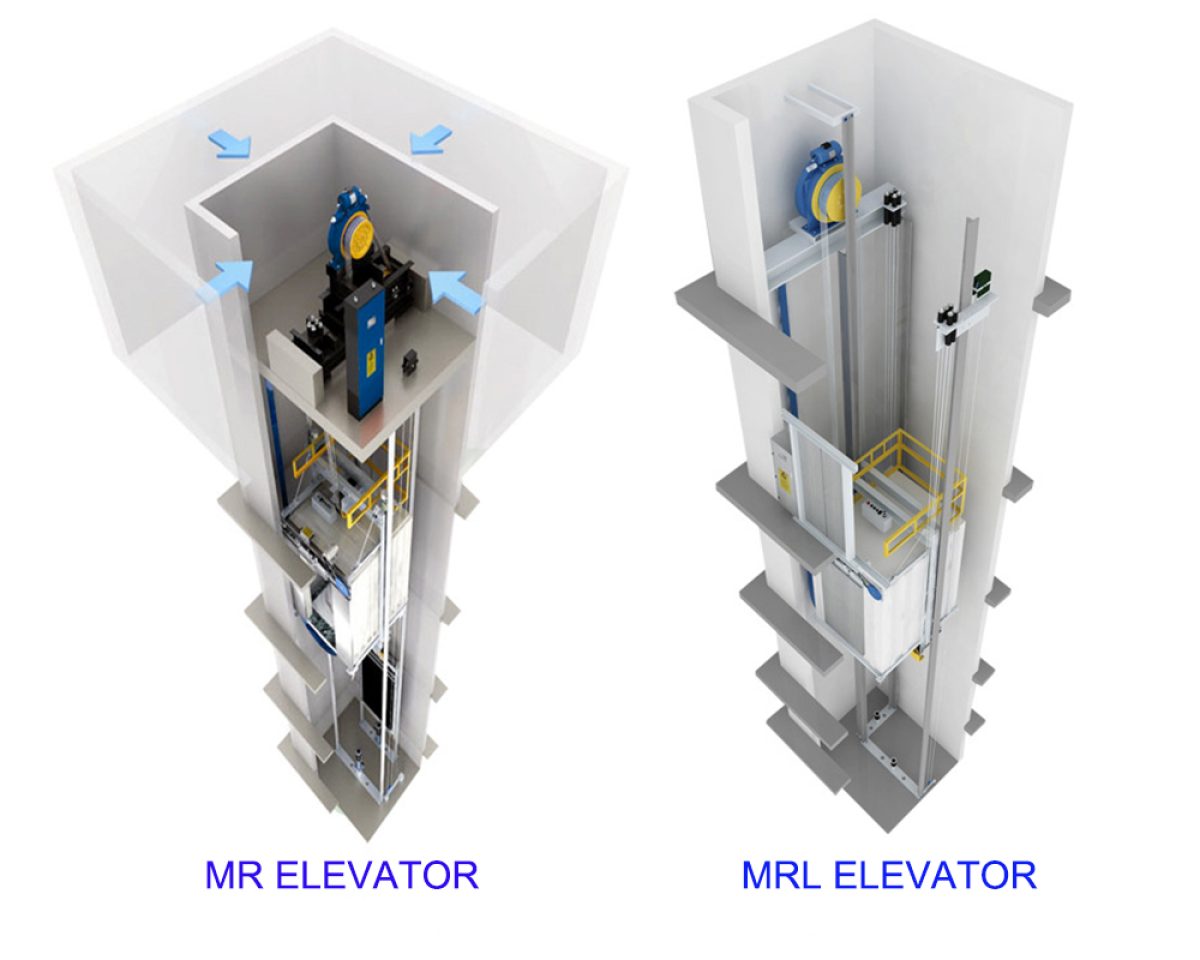

Machine room and shaft design have a direct impact on how effectively accessibility requirements can be implemented in passenger elevators. Early coordination between elevator suppliers, architects, and contractors is essential to ensure that structural conditions support accessible cabin sizes, door configurations, and safe installation. Well-planned shaft and machine room solutions also improve construction efficiency and long-term maintenance convenience, particularly in projects where space is limited or building layouts are complex.

Both machine-room-less (MRL) and machine-room (MR) passenger elevators can be designed to meet accessibility requirements. MRL elevators are often preferred in residential and mid-rise buildings due to space-saving benefits and flexible architectural integration. MR elevators, on the other hand, are commonly used in high-rise or heavy-duty applications where larger equipment and higher speeds are required. From an accessibility perspective, the key difference lies in installation planning rather than user experience, as cabin accessibility features remain consistent in both configurations.

Shaft dimensions and pit depth directly affect the feasibility of accessible elevator design. Adequate shaft width and depth are required to achieve compliant cabin sizes and door opening widths. Pit depth and top floor height must also meet minimum requirements to accommodate safety components and ensure smooth leveling accuracy. In renovation or modernization projects, customized shaft solutions are often necessary to balance structural constraints with accessibility standards.

Delfar designs passenger elevators with accessibility integrated into the core technical configuration rather than treated as an optional feature. By combining standardized engineering platforms with flexible customization, Delfar provides practical solutions that meet international accessibility expectations across residential, commercial, and public building projects. These solutions are developed to balance usability, safety, energy efficiency, and long-term reliability, making them suitable for both new construction and modernization projects.

Delfar passenger elevators for accessible applications are equipped with permanent magnet synchronous drive systems and advanced VVVF control technology, ensuring smooth acceleration, stable travel, and precise leveling. High-performance control systems support fault detection and automatic response functions, improving operational safety for all users. Infrared light curtain door protection and Class A energy efficiency further enhance safety and sustainability, making the elevators suitable for high-frequency public use environments.

Accessibility requirements often vary by building type and regional regulations. Delfar offers flexible customization options, including non-standard cabin dimensions, adjustable control panel layouts, and specialized interior configurations for hospitals or public buildings. Cabin finishes, handrail placement, and user interface features can be adapted to specific project needs, allowing developers and consultants to achieve compliance without compromising architectural design or functional performance.

Delfar’s accessible passenger elevators are engineered for diverse environments, combining reliability, safety, and user-centric design. From high-density residential towers to complex commercial hubs, our elevators ensure smooth vertical mobility while complying with global accessibility standards. Project experience across regions demonstrates our adaptability to local building codes and operational requirements, reinforcing confidence among architects, developers, and facility managers.

In high-rise residential developments, Delfar elevators provide consistent, accessible service for all residents, including the elderly and people with reduced mobility. Features such as wide cabins, low-threshold doors, and tactile control panels enhance convenience while adhering to accessibility guidelines. Reliable traction systems and smooth acceleration minimize ride discomfort, improving daily living experiences in multi-story homes.

Healthcare environments demand precise, safe, and responsive elevator solutions. Delfar’s accessible elevators for hospitals include priority operation modes for emergency transport, antimicrobial cabin surfaces, and seamless integration with medical equipment handling. Compliance with patient safety standards ensures that mobility challenges are mitigated for staff, patients, and visitors alike.

In shopping centers, office complexes, and mixed-use buildings, accessibility is a critical aspect of inclusivity and user satisfaction. Delfar elevators optimize passenger flow with energy-efficient motors, smart control systems, and ergonomic cabin layouts. Multi-stop programming and intelligent dispatching reduce waiting times, supporting high-traffic environments while maintaining accessibility compliance.

Delfar has delivered projects internationally, including Malaysia, the Middle East, and other regions with varied building regulations and environmental conditions. Our project teams provide localized engineering solutions, ensure proper installation, and adapt components to regional requirements, demonstrating our global capability to deliver safe, accessible, and reliable passenger elevators.

Reducing procurement and operational risks begins with meticulous installation planning and proactive maintenance strategies. Delfar provides comprehensive guidance from pre-installation design to intelligent long-term monitoring, ensuring that accessible elevators meet performance expectations and maintain reliability over their lifecycle.

Delfar engineers collaborate with architects and contractors during the planning phase. Detailed drawings, shaft evaluations, and space assessments ensure accurate specifications and seamless integration into building layouts. Early identification of potential conflicts minimizes delays and reduces modification costs during construction.

Before on-site installation, main machines, control cabinets, and cabins undergo thorough factory testing. Pre-assembly ensures dimensional accuracy and functional verification, allowing for faster installation and commissioning. This process significantly reduces on-site issues and guarantees operational consistency from day one.

A proactive maintenance plan ensures long-term elevator performance. Recommended inspection frequencies, from monthly checks to periodic component servicing, maintain safety and efficiency. Intelligent maintenance systems provide early warnings of potential issues, helping facility managers prevent downtime and extend the service life of critical components.

Delfar combines mature technology, global project experience, and cost-effective solutions. Our elevators are designed with accessibility as a core principle, using reliable components and responsive after-sales support. Custom-built solutions adapt to project-specific needs, giving developers and operators confidence in both performance and compliance.

High cost-performance ratio

Mature technology & reliable components

Proven international project experience

Responsive global after-sales support

Custom-built accessibility solutions

Accessible passenger elevators represent a long-term investment in safety, inclusivity, and building value. Delfar’s solutions combine proven technology, reliable components, and tailored designs to meet diverse project requirements worldwide. By prioritizing accessibility from planning to maintenance, developers and facility managers can ensure compliance with global standards, enhance user satisfaction, and deliver buildings that serve everyone effectively.

Monthly and annual inspections are recommended, with intelligent monitoring for early warning of operational issues.

Under proper maintenance, main components such as motors and traction systems exceed 10 years, while the full elevator design life often spans 20+ years.

Yes, Delfar provides flexible shaft design solutions to meet building constraints and accessibility standards.

Absolutely. Our elevators comply with international standards and have been installed in public buildings worldwide.